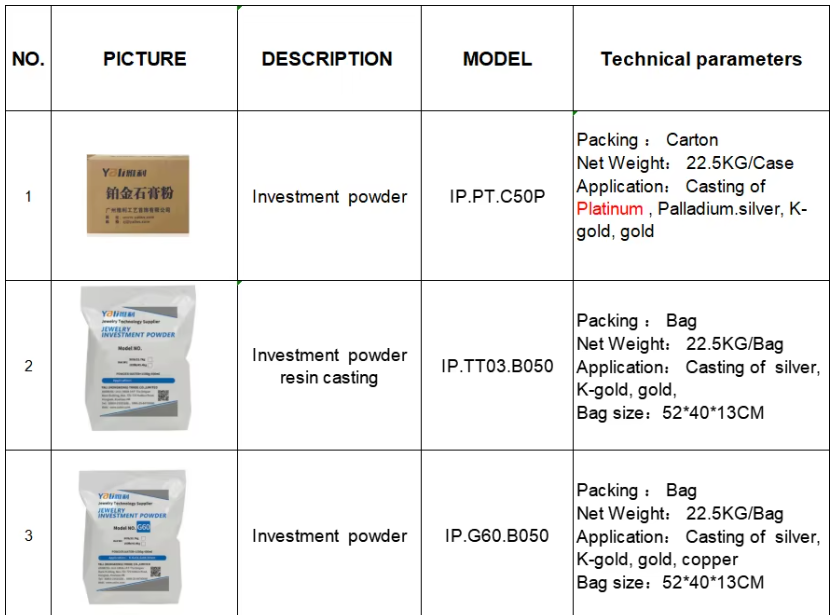

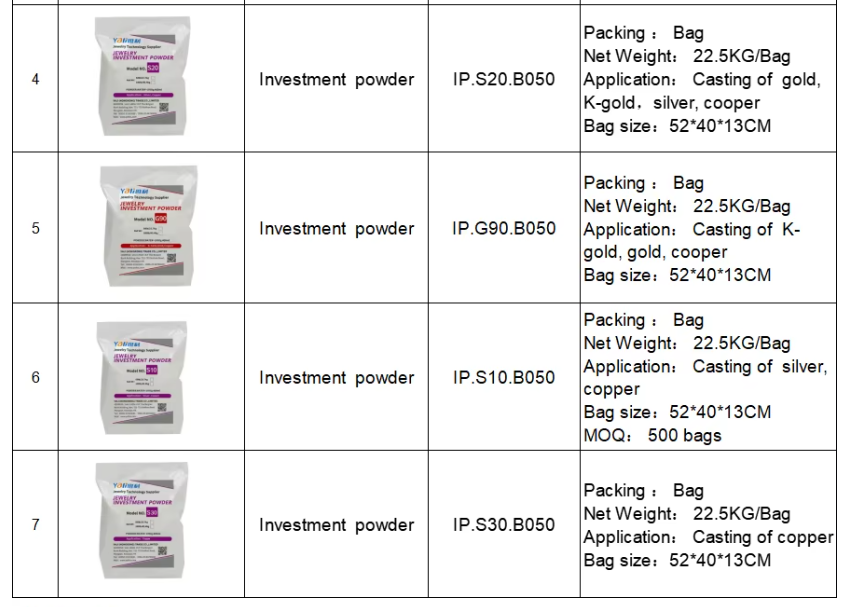

Jewelry Casting Investment Powder Gypsum Powder for Casting Resins

Jewelry Casting Investment Powder Gypsum Powder for Casting Resins

This gypsum-based investment powder is formulated for casting a range of noble metals. Designed to meet industry casting standards, it helps produce smooth surfaces, detailed features, and consistent results. Certified with ISO9001, this product aims to support the casting process and contribute to cost savings and improved efficiency.

Usage Instructions for Investment Powder:

1. Mixing Ratio:

Casting investment powder: 1000g

Water: 380-400ml (Water temperature around 22°C)

Steps:

Add water into the mixing chamber, then gradually add the investment powder.

Mix for 3-5 minutes until smooth.

Pour the mixture into the flask and vacuum for 1.5-2 minutes.

Wait 60-120 minutes for the flask to set before beginning the burn process.

2. Burn Process:

Increase the temperature evenly from 270°C to 730°C over 150 minutes.

Maintain 730°C for 180 minutes, then begin casting once the temperature drops to around 630°C.

Place the flasks in the oven, raise the temperature to 270°C within 60 minutes, and maintain 270°C for 180 minutes.

.jpg)

.jpg)

.jpg)